Product Description

Product Description

| OE NO. | 53534SDAA01 |

| Car Model | Honda Accord |

| Product Name | shock absorber dust cover |

| OEM | OEM Services Provided |

| Service | 24 Hours Customer Service |

| MOQ | 200pcs |

| Sample | Accept Sample |

| Warranty | 1 Years |

Company Profile

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Material: | Plastic |

| Samples: |

US$ 0.8/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the limitations of using plastic gears in industrial settings?

Using plastic gears in industrial settings has certain limitations. Here’s a detailed explanation of these limitations:

- Lower Load Capacity: Plastic gears generally have lower load-bearing capacities compared to metal gears. They are more susceptible to deformation and wear under heavy loads or high torque conditions. This makes them less suitable for applications that require withstanding substantial forces or transmitting high power.

- Temperature Sensitivity: Plastic gears have temperature limitations, and their performance can be affected by temperature variations. Some plastic materials may experience dimensional changes, loss of strength, or reduced stiffness at elevated temperatures. Additionally, high temperatures can accelerate wear and reduce the lifespan of plastic gears. Therefore, plastic gears may not be suitable for applications that involve high-temperature environments or extreme temperature fluctuations.

- Environmental Sensitivity: Plastic gears can be sensitive to certain environmental conditions. Certain plastic materials may degrade or become brittle when exposed to specific chemicals, solvents, oils, or UV radiation. This restricts their use in applications where exposure to harsh chemicals, lubricants, or outdoor elements is common.

- Wear and Abrasion: While plastic gears can offer good wear resistance, they are generally more prone to wear and abrasion compared to metal gears. Under heavy-load or high-speed conditions, the surface of plastic gears can wear down, leading to a decrease in performance and potential failure over time. Additional measures, such as incorporating reinforcements or using lubrication, may be necessary to mitigate wear in certain applications.

- Dimensional Stability: Plastic materials can have lower dimensional stability compared to metals. They may experience creep, shrinkage, or expansion over time, which can affect the accuracy and reliability of gear operation, particularly in applications with tight tolerances or precise gear meshing requirements.

- Impact Resistance: Plastic gears may have limited impact resistance compared to metal gears. They can be more susceptible to damage or fracture when subjected to sudden impact or shock loads. This makes them less suitable for applications with high impact or heavy-duty requirements.

- Compatibility with Existing Systems: In some cases, replacing metal gears with plastic gears may require modifications to the existing system. Plastic gears may have different dimensions, mounting requirements, or gear ratios compared to metal gears, necessitating design changes or adaptations to accommodate the use of plastic gears.

Despite these limitations, plastic gears can still offer significant advantages in certain industrial settings, such as reduced weight, noise reduction, and cost-effectiveness. It’s crucial to carefully evaluate the specific application requirements and consider the trade-offs between the benefits and limitations of plastic gears when deciding whether they are suitable for a particular industrial setting.

Are there specific design considerations for using plastic gears?

Yes, there are specific design considerations that need to be taken into account when using plastic gears. Here’s a detailed explanation of these considerations:

1. Material Selection: Choosing the right plastic material for the gear application is crucial. Different plastic materials have varying mechanical properties, such as strength, stiffness, and wear resistance. Consider factors such as load-bearing requirements, operating temperatures, environmental conditions, and compatibility with lubricants. It’s important to select a plastic material that can withstand the specific demands of the application.

2. Gear Geometry: The design of plastic gears should consider factors such as tooth profile, module or pitch, pressure angle, and tooth thickness. The gear geometry should be optimized to ensure proper meshing, efficient power transmission, and minimal noise and vibration. The design should also take into account the limitations and capabilities of the plastic material, such as its ability to form precise tooth profiles and maintain dimensional stability.

3. Clearances and Tolerances: Plastic gears may require different clearances and tolerances compared to metal gears. The coefficient of thermal expansion, dimensional stability, and manufacturing processes of plastic materials can affect the gear clearances. It’s important to consider the thermal expansion characteristics of the specific plastic material and provide appropriate clearances to accommodate temperature variations. Tight tolerances may result in binding or increased friction, while excessive clearances can lead to backlash and reduced gear accuracy.

4. Load Distribution: Distributing the load evenly across the gear teeth is essential for preventing premature wear and failure. Consider gear design elements such as tooth profile, tooth width, and the number of teeth to optimize load distribution. Reinforcing the gear teeth with fillets or other strengthening features can help improve load-bearing capacity and reduce stress concentrations.

5. Stiffness and Deflection: Plastic gears generally have lower stiffness compared to metal gears. The design should consider the potential for deflection or deformation under load. It may be necessary to increase the gear size, modify the tooth geometry, or incorporate additional support structures to enhance stiffness and minimize deflection. Analytical tools and simulations can be employed to assess and optimize gear design for stiffness and deflection.

6. Lubrication and Wear: Proper lubrication is important for the performance and durability of plastic gears. Consider the lubrication requirements of the specific plastic material and design features that facilitate effective lubricant distribution. Pay attention to potential wear mechanisms, such as adhesive wear or abrasive wear, and incorporate measures to minimize wear, such as optimized tooth profiles, lubricant selection, and sealing mechanisms.

7. Environmental Factors: Plastic gears may be subjected to various environmental factors such as temperature extremes, humidity, chemicals, and UV exposure. Evaluate the potential impact of these factors on the gear material and design. Select plastic materials that offer resistance to environmental degradation and consider protective measures, such as coatings or encapsulation, to enhance the gear’s resistance to environmental conditions.

8. Manufacturability: Consider the manufacturability of plastic gears during the design phase. Different plastic materials may have specific requirements or limitations for manufacturing processes such as injection molding or machining. Design features that facilitate efficient and cost-effective production, such as draft angles, parting lines, and tooling considerations, should be taken into account.

By considering these specific design considerations, such as material selection, gear geometry, clearances, load distribution, stiffness, lubrication, environmental factors, and manufacturability, it’s possible to optimize the design and performance of plastic gears for various applications.

What industries commonly use plastic gears?

Plastic gears find applications in various industries due to their unique properties and advantages. Here’s a detailed explanation of the industries that commonly use plastic gears:

- Automotive: Plastic gears are used in automotive applications such as power windows, seat adjusters, HVAC systems, windshield wipers, and various motor-driven mechanisms. Their lightweight nature, noise reduction capabilities, and corrosion resistance make them suitable for these applications.

- Consumer Electronics: Plastic gears are used in consumer electronics devices like printers, scanners, cameras, and audio equipment. Their lightweight construction, low noise generation, and design flexibility make them ideal for compact and noise-sensitive applications.

- Medical: Plastic gears are utilized in medical devices and equipment such as pumps, lab instruments, diagnostic devices, and surgical equipment. Their corrosion resistance, lubricity, and ability to be sterilized make them suitable for medical environments.

- Office Equipment: Plastic gears are commonly found in office equipment like printers, photocopiers, scanners, and shredders. Their low noise operation, lightweight construction, and cost-effectiveness make them popular choices in these applications.

- Industrial Machinery: Plastic gears are used in various industrial machinery applications, including packaging equipment, conveyor systems, material handling equipment, and small gearboxes. Their self-lubricating properties, corrosion resistance, and noise reduction capabilities make them suitable for these industrial environments.

- Toys and Games: Plastic gears are extensively used in toys, hobbyist models, and games. Their lightweight nature, cost-effectiveness, and ease of customization allow for the creation of intricate moving parts in these recreational products.

- Aerospace: Plastic gears are used in certain aerospace applications, particularly in non-critical systems such as cabin equipment, small actuators, and control mechanisms. Their lightweight construction and noise reduction characteristics are advantageous in aerospace applications.

- Telecommunications: Plastic gears find applications in telecommunications equipment such as routers, switches, and communication devices. Their lightweight design, noise reduction properties, and cost-effectiveness make them suitable for these applications.

These are just a few examples of the industries that commonly use plastic gears. The versatility, cost-effectiveness, design flexibility, and specific performance characteristics of plastic gears make them valuable components in numerous applications across various sectors.

editor by Dream 2024-05-02

China Custom 4G0909144L Fits Audi A6 C7 / A7 Rhd Power Steering Gear worm gearbox

Product Description

Product Description

| Product Name | 4G57144L Fits Audi A6 C7 / A7 RHD Power Steering Gear |

| Application | Audi A6L / A7 / RS7 / C7 / 1N8 Automobile Steering system |

| OEM NO |

4G57144L |

| Car Make | Audi A6L / A7 / RS7 / C7 / 1N8 |

| Warranty | 12 Months |

| Weight | 16KG |

| Drive Xihu (West Lake) Dis. | RHD |

| Type | Electronic |

| ZUA NO | F-VW-106 |

Our Advantages

Company Profile

Exhibition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24-Hour on-Line |

|---|---|

| Warranty: | 12 Months |

| Type: | Steering Rack |

| Samples: |

US$ 599/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

What are the factors affecting the durability of plastic gears?

The durability of plastic gears can be influenced by various factors. Here’s a detailed explanation of these factors:

1. Material Selection: The choice of plastic material is a critical factor affecting the durability of plastic gears. Different plastic materials have varying mechanical properties, including strength, stiffness, impact resistance, and wear resistance. Selecting a material with suitable properties for the specific application is essential to ensure long-term durability.

2. Load and Stress: The magnitude and distribution of the applied load significantly impact the durability of plastic gears. Excessive loads or high stress concentrations can lead to deformation, fatigue, or even failure of the gear teeth. Proper consideration of the anticipated loads and stress distribution is crucial during the design phase to ensure that the gears can withstand the expected operating conditions.

3. Operating Speed: The rotational speed at which the plastic gears operate can affect their durability. Higher speeds can generate more heat due to friction, potentially leading to thermal degradation or wear. The material selection and design should account for the anticipated operating speeds to ensure that the gears can withstand the associated stresses and temperature rise without compromising their durability.

4. Lubrication: Proper lubrication is vital for reducing friction, minimizing wear, and enhancing the durability of plastic gears. Insufficient or improper lubrication can result in increased friction, leading to accelerated wear and potential gear failure. The selection of suitable lubricants and appropriate lubrication methods is essential to ensure optimal performance and durability.

5. Environmental Conditions: The environmental conditions in which plastic gears operate can impact their durability. Factors such as temperature extremes, humidity, exposure to chemicals or UV radiation, and presence of abrasive particles can degrade the plastic material over time. It’s important to consider the anticipated environmental conditions and select a plastic material that offers sufficient resistance to these factors.

6. Gear Design: The design of plastic gears can greatly influence their durability. Factors such as tooth profile, gear geometry, clearances, and load distribution should be optimized to minimize stress concentrations, prevent excessive wear, and ensure even load distribution across the gear teeth. Proper design considerations, including appropriate fillets, reinforcements, and tooth profiles, can improve the durability of plastic gears.

7. Manufacturing Quality: The quality of the manufacturing process and the precision of the gear manufacturing can impact its durability. Inadequate manufacturing processes or poor quality control can result in dimensional inaccuracies, surface defects, or material inconsistencies that can compromise the gear’s durability. Ensuring high-quality manufacturing practices and inspections is essential to maintain the durability of plastic gears.

8. Maintenance and Service Life: The maintenance practices and service life of plastic gears can affect their durability. Regular inspection, proper lubrication, and timely replacement of worn or damaged gears can help extend their lifespan. Neglecting maintenance or operating gears beyond their intended service life can lead to accelerated wear and reduced durability.

By considering these factors, such as material selection, load and stress, operating speed, lubrication, environmental conditions, gear design, manufacturing quality, and maintenance practices, it’s possible to optimize the durability of plastic gears and ensure their long-term performance.

What industries commonly use plastic gears?

Plastic gears find applications in various industries due to their unique properties and advantages. Here’s a detailed explanation of the industries that commonly use plastic gears:

- Automotive: Plastic gears are used in automotive applications such as power windows, seat adjusters, HVAC systems, windshield wipers, and various motor-driven mechanisms. Their lightweight nature, noise reduction capabilities, and corrosion resistance make them suitable for these applications.

- Consumer Electronics: Plastic gears are used in consumer electronics devices like printers, scanners, cameras, and audio equipment. Their lightweight construction, low noise generation, and design flexibility make them ideal for compact and noise-sensitive applications.

- Medical: Plastic gears are utilized in medical devices and equipment such as pumps, lab instruments, diagnostic devices, and surgical equipment. Their corrosion resistance, lubricity, and ability to be sterilized make them suitable for medical environments.

- Office Equipment: Plastic gears are commonly found in office equipment like printers, photocopiers, scanners, and shredders. Their low noise operation, lightweight construction, and cost-effectiveness make them popular choices in these applications.

- Industrial Machinery: Plastic gears are used in various industrial machinery applications, including packaging equipment, conveyor systems, material handling equipment, and small gearboxes. Their self-lubricating properties, corrosion resistance, and noise reduction capabilities make them suitable for these industrial environments.

- Toys and Games: Plastic gears are extensively used in toys, hobbyist models, and games. Their lightweight nature, cost-effectiveness, and ease of customization allow for the creation of intricate moving parts in these recreational products.

- Aerospace: Plastic gears are used in certain aerospace applications, particularly in non-critical systems such as cabin equipment, small actuators, and control mechanisms. Their lightweight construction and noise reduction characteristics are advantageous in aerospace applications.

- Telecommunications: Plastic gears find applications in telecommunications equipment such as routers, switches, and communication devices. Their lightweight design, noise reduction properties, and cost-effectiveness make them suitable for these applications.

These are just a few examples of the industries that commonly use plastic gears. The versatility, cost-effectiveness, design flexibility, and specific performance characteristics of plastic gears make them valuable components in numerous applications across various sectors.

editor by Dream 2024-04-30

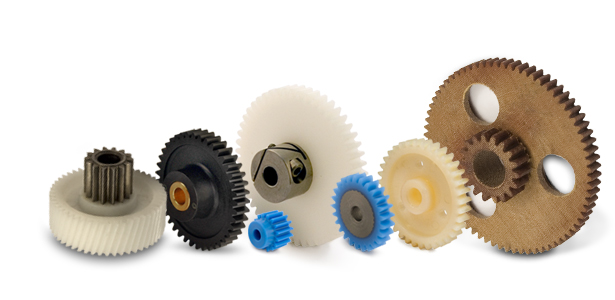

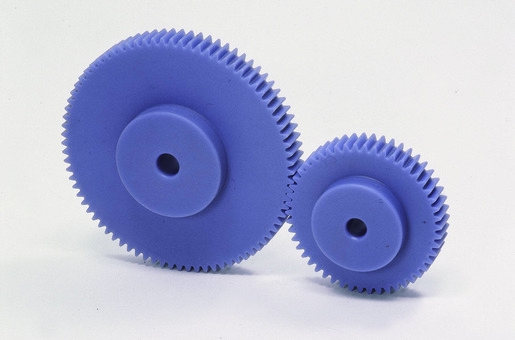

China Professional German Atotech Gears Equipment Double Gears Bevel Gears Supr Gears Helical Gear Conveyor Gears PVDF Gears hypoid bevel gear

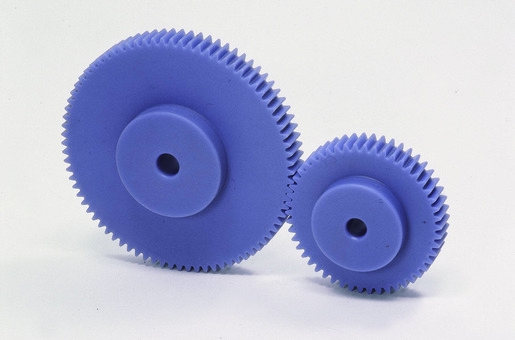

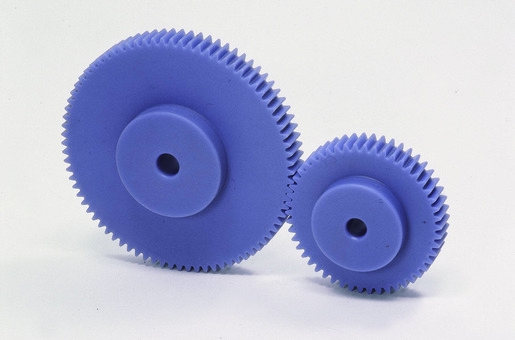

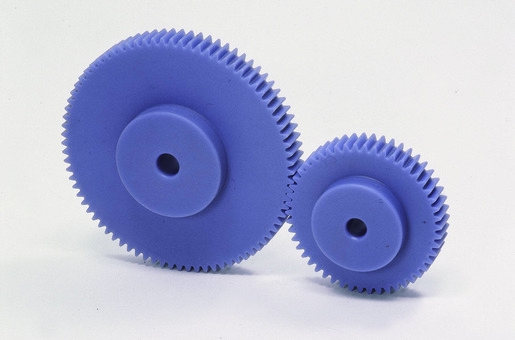

Product Description

Product Description

Gears, are widely used in conveyor system. According to the shape, there are spur gear, bevel gear, helical gear, pin gear, double gear and etc. According the using situation, gears involved in driving gears and drived gears. According to different using environment, there are different materials to choice, such as: HCPP, PVDF, PVC, POM, PA, PFA, PEEK, ETFE and etc. Main parameter for gears, there are: ID, OD, Teeth quantity, M, Length, Center circle. As we know: M*Teeth quantity=Center circle, so if you have any requirements, pls contact with us. We have professional design team, we can design drawing and choose suitable material for you, as your requirements.

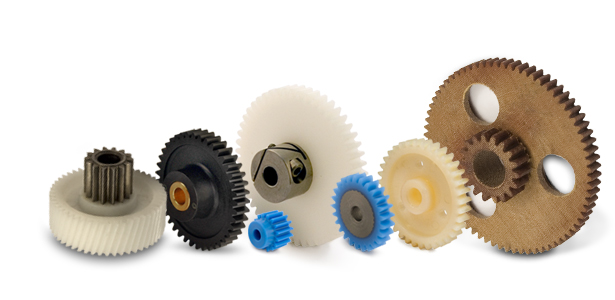

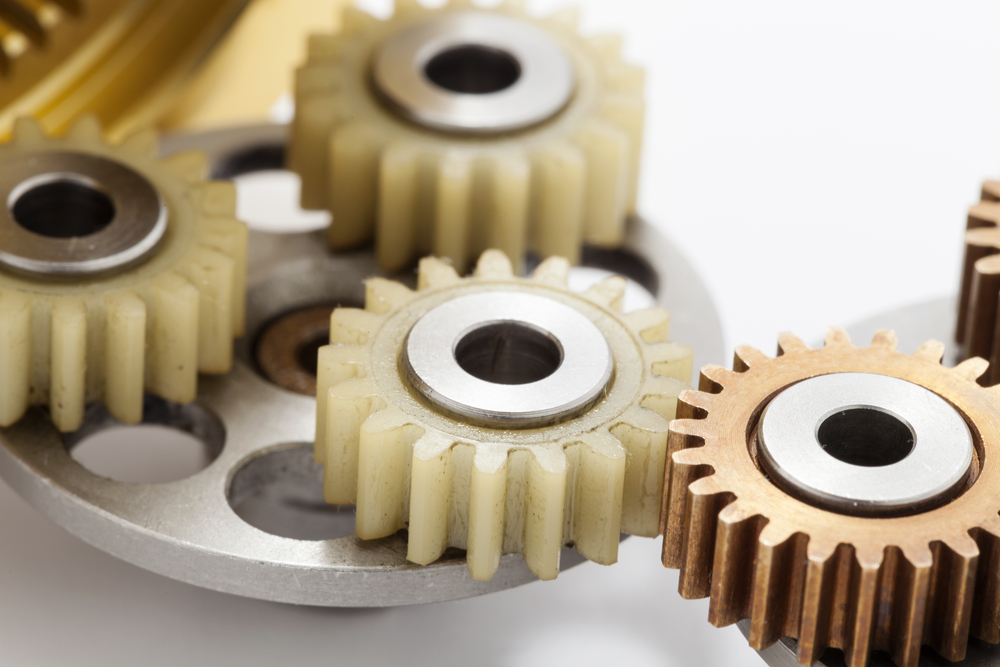

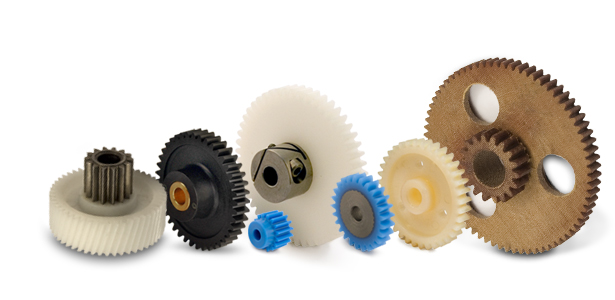

Detailed Photos

Features

1- wear-resistant

2- corrosion resistance

3- transfer smooth

4- low transmission sound

5- easy to install and repair replacement

Product Parameters

| Name | Material | ID | Center Circle |

| Spur Gear | HCPP, PVDF, PVC, POM, PA, PFA, PEEK, ETFE and etc. | ID8, ID10, ID12, ID12.7, ID15, ID16 and etc. | 16, 18, 20, 22, 24, 25, 30, 32, 35, 40, 48, 50 and etc. |

| Bevel Gear | |||

| Helical Gear | |||

| Pin Gear | |||

| Double Gear |

Note: If you need order gears, pls provide the data as the drawing:

Other Products

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How to order ?

A: Normally you can order our products by using Made-in China platform or contacting representatives by Email.

After we receive your messages, we will help you to choose the right specifications and other inquiries.

Then we will send an proforma invoice to you via mail, it includes details of your order and our bank information.

After we received your payment by TT, we will ship your goods and we will send the invoice, packing list, and the express tracking number via mail.

Q: What is our term of trade ?

A: Usually we use EX WORKS. If you need other term of trade, please let us know.

Q: How to pay ?

A: We accept the payment by T/T (bank transfer) or pay through Made-in China platform.

Please inquire us about the details in advance.

Q: How are you going to deliver our goods ?

A: We can ship your goods either by air express (FedEx, DHL, UPS, TNT etc) or by sea.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | PCB Machine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Injection Molding |

| Toothed Portion Shape: | Double Gear |

| Material: | Plastic |

| Samples: |

US$ 2.6/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

How do plastic gears handle lubrication and wear?

Plastic gears handle lubrication and wear differently compared to metal gears. Here’s a detailed explanation of their behavior:

1. Lubrication in Plastic Gears: Lubrication plays a crucial role in the performance and longevity of plastic gears. While metal gears often require continuous lubrication, plastic gears have different lubrication requirements due to their inherent properties. Here are some key considerations:

- Self-Lubrication: Some plastic materials, such as certain formulations of polyoxymethylene (POM), have inherent self-lubricating properties. These materials have a low coefficient of friction and can operate with minimal lubrication or even dry. Self-lubricating plastic gears can be advantageous in applications where the use of external lubricants is impractical or undesirable.

- Lubricant Compatibility: When external lubrication is necessary, it’s important to choose lubricants that are compatible with the specific plastic material used in the gears. Certain lubricants may degrade or adversely affect the mechanical properties of certain plastics. Consultation with lubricant manufacturers or experts can help identify suitable lubricants that won’t cause degradation or wear issues.

- Reduced Lubricant Requirements: Plastic gears generally have lower friction coefficients compared to metal gears. This reduced friction results in lower heat generation and less wear, which in turn reduces the demand for lubrication. Plastic gears may require less frequent lubricant replenishment or lower lubricant volumes, reducing maintenance requirements.

- Appropriate Lubricant Application: When applying lubricant to plastic gears, care should be taken to avoid excessive amounts that could lead to contamination or leakage. Lubricants should be applied in a controlled manner, ensuring they reach the critical contact points without excessive buildup or excess spreading beyond the gear surfaces.

2. Wear in Plastic Gears: Plastic gears exhibit different wear characteristics compared to metal gears. While metal gears typically experience gradual wear due to surface interactions, plastic gears may undergo different types of wear mechanisms, including:

- Adhesive Wear: Adhesive wear can occur in plastic gears when high loads or speeds cause localized melting or deformation at the gear teeth contact points. This can result in material transfer between gear surfaces and increased wear. Proper material selection, gear design optimization, and lubrication can help minimize adhesive wear in plastic gears.

- Abrasive Wear: Abrasive wear in plastic gears can be caused by the presence of abrasive particles or contaminants in the operating environment. These particles can act as abrasive agents, gradually wearing down the gear surfaces. Implementing effective filtration or sealing mechanisms, along with proper maintenance practices, can help reduce abrasive wear in plastic gears.

- Fatigue Wear: Plastic materials can exhibit fatigue wear under cyclic loading conditions. Repeated stress and deformation cycles can lead to crack initiation and propagation, ultimately resulting in gear failure. Proper gear design, material selection, and avoiding excessive loads or stress concentrations can help mitigate fatigue wear in plastic gears.

3. Gear Material Selection: The choice of plastic material for gears can significantly impact their lubrication and wear characteristics. Different plastic materials have varying coefficients of friction, wear resistance, and compatibility with lubricants. It’s important to select materials that offer suitable lubrication and wear properties for the specific application requirements.

4. Operational Considerations: Proper operating conditions and practices can also contribute to the effective handling of lubrication and wear in plastic gears. Avoiding excessive loads, controlling operating temperatures within the material’s limits, implementing effective maintenance procedures, and monitoring gear performance are essential for ensuring optimal gear operation and minimizing wear.

In summary, plastic gears can handle lubrication and wear differently compared to metal gears. They may exhibit self-lubricating properties, reduced lubricant requirements, and require careful consideration of lubricant compatibility. Plastic gears can experience different types of wear, including adhesive wear, abrasive wear, and fatigue wear. Proper material selection, gear design, lubrication practices, and operational considerations are crucial for ensuring efficient lubrication and minimizing wear in plastic gears.

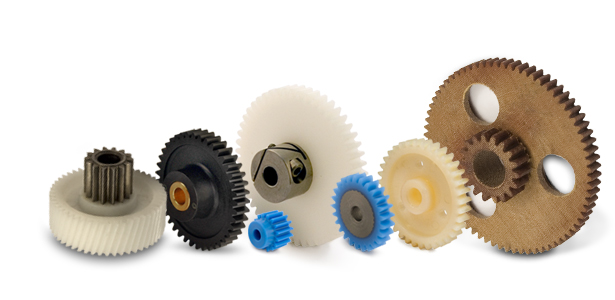

What are plastic gears and how are they used?

Plastic gears are gear components made from various types of polymers or plastic materials. They offer unique properties and advantages compared to traditional metal gears. Here’s a detailed explanation of plastic gears and their applications:

- Types of Plastic Materials: Plastic gears can be manufactured from different types of polymers, including thermoplastics such as acetal (polyoxymethylene – POM), nylon (polyamide – PA), polycarbonate (PC), and polyethylene (PE), as well as thermosetting plastics like phenolic resins. Each material has its own specific characteristics, such as strength, wear resistance, and temperature resistance, which make them suitable for different applications.

- Advantages of Plastic Gears: Plastic gears offer several advantages over metal gears, including:

- Lightweight: Plastic gears are lighter in weight compared to metal gears, which can be beneficial in applications where weight reduction is important.

- Low Noise and Vibration: Plastic gears can provide quieter operation due to their inherent damping properties that reduce noise and vibration levels.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals, making them suitable for applications in corrosive environments.

- Self-Lubrication: Some plastic materials have self-lubricating properties, reducing the need for external lubrication and simplifying maintenance.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production, due to the lower material and manufacturing costs.

- Applications of Plastic Gears: Plastic gears find applications in various industries and systems, including:

- Automotive: Plastic gears are used in automotive systems such as windshield wipers, HVAC systems, seat adjusters, and electric power steering systems.

- Consumer Electronics: Plastic gears are commonly found in consumer electronics like printers, scanners, cameras, and home appliances.

- Medical Devices: Plastic gears are used in medical equipment and devices where weight reduction, low noise, and corrosion resistance are desired.

- Toy Manufacturing: Plastic gears are extensively used in the production of toys, including mechanical toys, hobby models, and educational kits.

- Office Equipment: Plastic gears are employed in office equipment like printers, copiers, and scanners, where quiet operation and cost-effectiveness are important.

- Industrial Machinery: Plastic gears can be utilized in various industrial machinery applications, such as conveyor systems, packaging equipment, and textile machinery.

It’s important to note that while plastic gears offer unique advantages, they also have limitations. They may not be suitable for applications requiring extremely high torque, high temperatures, or where precise positioning is critical. The selection of plastic gears should consider the specific requirements of the application and the mechanical properties of the chosen plastic material.

editor by Dream 2024-04-29

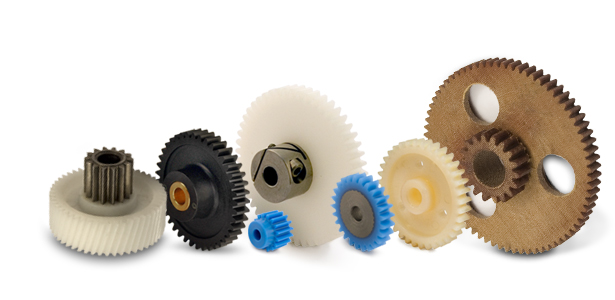

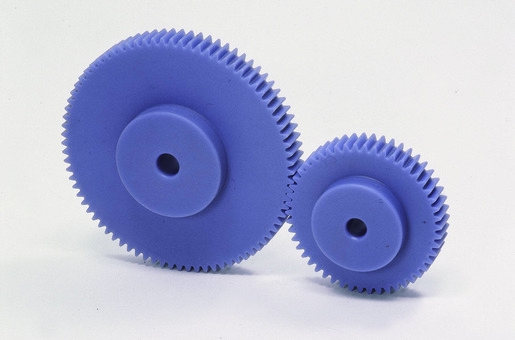

China factory Small Plastic Gear for Injection Molding Barlles with Great quality

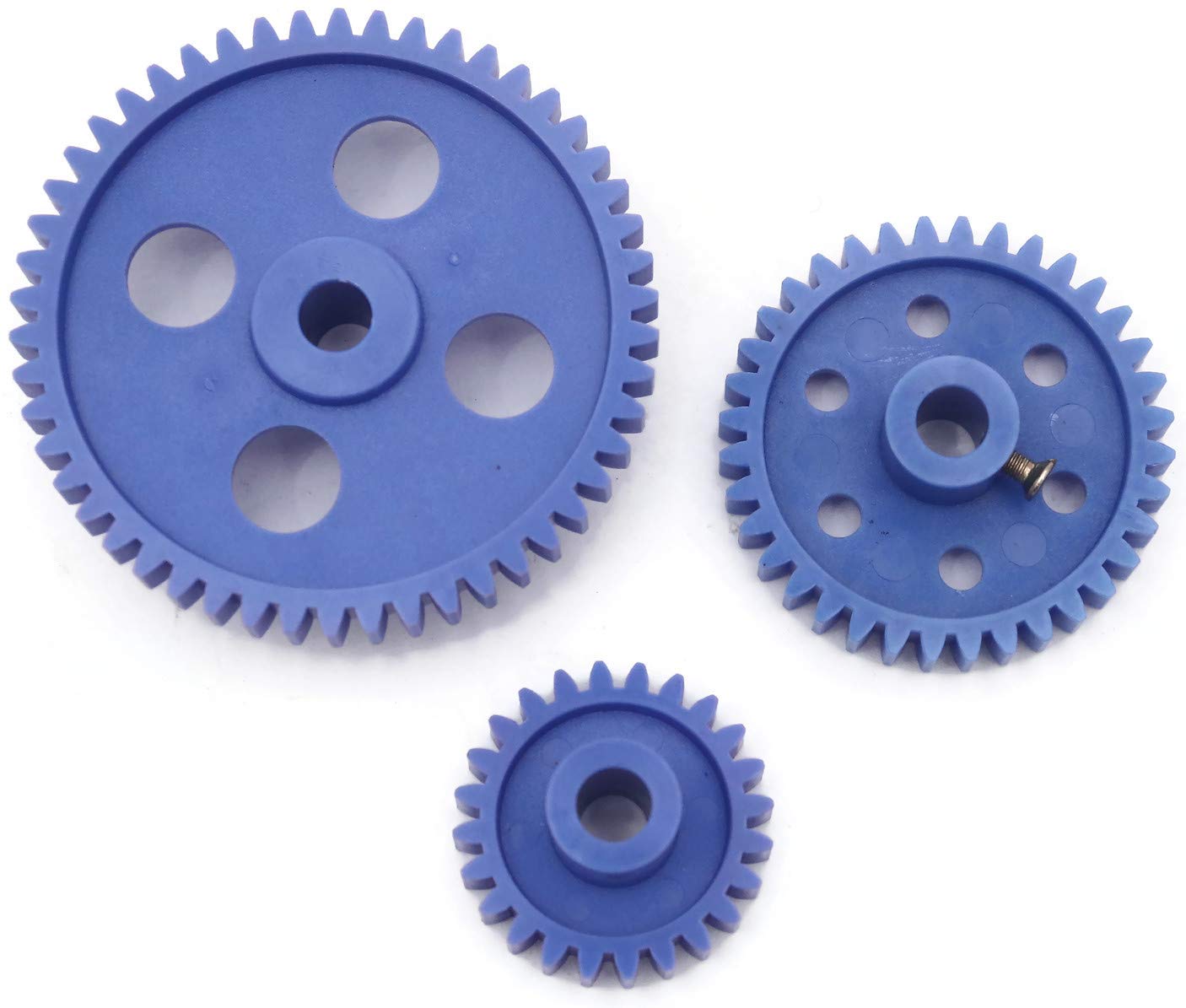

Product Description

Product Description

Gears, are widely used in conveyor system. According to the shape, there are spur gear, bevel gear, helical gear, pin gear, double gear and etc. According the using situation, gears involved in driving gears and drived gears. According to different using environment, there are different materials to choice, such as: HCPP, PVDF, PVC, POM, PA, PFA, PEEK, ETFE and etc. Main parameter for gears, there are: ID, OD, Teeth quantity, M, Length, Center circle. As we know: M*Teeth quantity=Center circle, so if you have any requirements, pls contact with us. We have professional design team, we can design drawing and choose suitable material for you, as your requirements.

Detailed Photos

Features

1- wear-resistant

2- corrosion resistance

3- transfer smooth

4- low transmission sound

5- easy to install and repair replacement

Product Parameters

| Name | Material | ID | Center Circle |

| Spur Gear | HCPP, PVDF, PVC, POM, PA, PFA, PEEK, ETFE and etc. | ID8, ID10, ID12, ID12.7, ID15, ID16 and etc. | 16, 18, 20, 22, 24, 25, 30, 32, 35, 40, 48, 50 and etc. |

| Bevel Gear | |||

| Helical Gear | |||

| Pin Gear | |||

| Double Gear |

Note: If you need order gears, pls provide the data as the drawing:

Other Products

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How to order ?

A: Normally you can order our products by using Made-in China platform or contacting representatives by Email.

After we receive your messages, we will help you to choose the right specifications and other inquiries.

Then we will send an proforma invoice to you via mail, it includes details of your order and our bank information.

After we received your payment by TT, we will ship your goods and we will send the invoice, packing list, and the express tracking number via mail.

Q: What is our term of trade ?

A: Usually we use EX WORKS. If you need other term of trade, please let us know.

Q: How to pay ?

A: We accept the payment by T/T (bank transfer) or pay through Made-in China platform.

Please inquire us about the details in advance.

Q: How are you going to deliver our goods ?

A: We can ship your goods either by air express (FedEx, DHL, UPS, TNT etc) or by sea.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | PCB Machine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Injection Molding |

| Toothed Portion Shape: | Spur Gear |

| Material: | Plastic |

| Samples: |

US$ 0.4/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the limitations of using plastic gears in industrial settings?

Using plastic gears in industrial settings has certain limitations. Here’s a detailed explanation of these limitations:

- Lower Load Capacity: Plastic gears generally have lower load-bearing capacities compared to metal gears. They are more susceptible to deformation and wear under heavy loads or high torque conditions. This makes them less suitable for applications that require withstanding substantial forces or transmitting high power.

- Temperature Sensitivity: Plastic gears have temperature limitations, and their performance can be affected by temperature variations. Some plastic materials may experience dimensional changes, loss of strength, or reduced stiffness at elevated temperatures. Additionally, high temperatures can accelerate wear and reduce the lifespan of plastic gears. Therefore, plastic gears may not be suitable for applications that involve high-temperature environments or extreme temperature fluctuations.

- Environmental Sensitivity: Plastic gears can be sensitive to certain environmental conditions. Certain plastic materials may degrade or become brittle when exposed to specific chemicals, solvents, oils, or UV radiation. This restricts their use in applications where exposure to harsh chemicals, lubricants, or outdoor elements is common.

- Wear and Abrasion: While plastic gears can offer good wear resistance, they are generally more prone to wear and abrasion compared to metal gears. Under heavy-load or high-speed conditions, the surface of plastic gears can wear down, leading to a decrease in performance and potential failure over time. Additional measures, such as incorporating reinforcements or using lubrication, may be necessary to mitigate wear in certain applications.

- Dimensional Stability: Plastic materials can have lower dimensional stability compared to metals. They may experience creep, shrinkage, or expansion over time, which can affect the accuracy and reliability of gear operation, particularly in applications with tight tolerances or precise gear meshing requirements.

- Impact Resistance: Plastic gears may have limited impact resistance compared to metal gears. They can be more susceptible to damage or fracture when subjected to sudden impact or shock loads. This makes them less suitable for applications with high impact or heavy-duty requirements.

- Compatibility with Existing Systems: In some cases, replacing metal gears with plastic gears may require modifications to the existing system. Plastic gears may have different dimensions, mounting requirements, or gear ratios compared to metal gears, necessitating design changes or adaptations to accommodate the use of plastic gears.

Despite these limitations, plastic gears can still offer significant advantages in certain industrial settings, such as reduced weight, noise reduction, and cost-effectiveness. It’s crucial to carefully evaluate the specific application requirements and consider the trade-offs between the benefits and limitations of plastic gears when deciding whether they are suitable for a particular industrial setting.

What are the factors affecting the durability of plastic gears?

The durability of plastic gears can be influenced by various factors. Here’s a detailed explanation of these factors:

1. Material Selection: The choice of plastic material is a critical factor affecting the durability of plastic gears. Different plastic materials have varying mechanical properties, including strength, stiffness, impact resistance, and wear resistance. Selecting a material with suitable properties for the specific application is essential to ensure long-term durability.

2. Load and Stress: The magnitude and distribution of the applied load significantly impact the durability of plastic gears. Excessive loads or high stress concentrations can lead to deformation, fatigue, or even failure of the gear teeth. Proper consideration of the anticipated loads and stress distribution is crucial during the design phase to ensure that the gears can withstand the expected operating conditions.

3. Operating Speed: The rotational speed at which the plastic gears operate can affect their durability. Higher speeds can generate more heat due to friction, potentially leading to thermal degradation or wear. The material selection and design should account for the anticipated operating speeds to ensure that the gears can withstand the associated stresses and temperature rise without compromising their durability.

4. Lubrication: Proper lubrication is vital for reducing friction, minimizing wear, and enhancing the durability of plastic gears. Insufficient or improper lubrication can result in increased friction, leading to accelerated wear and potential gear failure. The selection of suitable lubricants and appropriate lubrication methods is essential to ensure optimal performance and durability.

5. Environmental Conditions: The environmental conditions in which plastic gears operate can impact their durability. Factors such as temperature extremes, humidity, exposure to chemicals or UV radiation, and presence of abrasive particles can degrade the plastic material over time. It’s important to consider the anticipated environmental conditions and select a plastic material that offers sufficient resistance to these factors.

6. Gear Design: The design of plastic gears can greatly influence their durability. Factors such as tooth profile, gear geometry, clearances, and load distribution should be optimized to minimize stress concentrations, prevent excessive wear, and ensure even load distribution across the gear teeth. Proper design considerations, including appropriate fillets, reinforcements, and tooth profiles, can improve the durability of plastic gears.

7. Manufacturing Quality: The quality of the manufacturing process and the precision of the gear manufacturing can impact its durability. Inadequate manufacturing processes or poor quality control can result in dimensional inaccuracies, surface defects, or material inconsistencies that can compromise the gear’s durability. Ensuring high-quality manufacturing practices and inspections is essential to maintain the durability of plastic gears.

8. Maintenance and Service Life: The maintenance practices and service life of plastic gears can affect their durability. Regular inspection, proper lubrication, and timely replacement of worn or damaged gears can help extend their lifespan. Neglecting maintenance or operating gears beyond their intended service life can lead to accelerated wear and reduced durability.

By considering these factors, such as material selection, load and stress, operating speed, lubrication, environmental conditions, gear design, manufacturing quality, and maintenance practices, it’s possible to optimize the durability of plastic gears and ensure their long-term performance.

Can plastic gears replace metal gears in certain applications?

Yes, plastic gears can replace metal gears in certain applications. Here’s a detailed explanation:

Plastic gears offer a range of advantages that make them suitable alternatives to metal gears in specific scenarios. Some of the factors that determine whether plastic gears can replace metal gears include the application requirements, operating conditions, load capacity, and desired performance characteristics.

Advantages of Plastic Gears:

- Lightweight: Plastic gears are significantly lighter than metal gears, making them suitable for applications where weight reduction is important. This can lead to energy efficiency, reduced inertia, and lower wear on supporting components.

- Low Noise and Vibration: Plastic gears have inherent damping properties that help reduce noise and vibration levels during operation. This makes them suitable for applications where noise reduction is desired, such as in consumer electronics or office equipment.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals. Plastic gears can be a suitable choice for applications in corrosive environments where metal gears may suffer from degradation.

- Self-Lubrication: Some plastic materials used for gear manufacturing have self-lubricating properties. This reduces friction and wear between gear teeth, eliminating the need for external lubrication and simplifying maintenance requirements.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production. Plastic materials are often less expensive than metals, and the manufacturing processes for plastic gears can be more efficient.

- Design Flexibility: Plastic gears offer greater design flexibility compared to metal gears. They can be molded into complex shapes, allowing for custom gear profiles and tooth geometries, resulting in optimized performance and efficiency for specific applications.

Limitations of Plastic Gears:

- High Torque and Load Capacity: Plastic gears may not have the same torque and load capacity as metal gears. In applications requiring high torque or heavy loads, metal gears may be more suitable due to their higher strength and durability.

- High Temperatures: Plastic gears have temperature limitations depending on the chosen material. In applications with high operating temperatures, metal gears that can withstand the heat may be necessary.

- Precision and Positioning: Plastic gears may not offer the same level of precision and positioning accuracy as metal gears. Applications that require tight tolerances and precise gear meshing may still require metal gears.

In summary, plastic gears can replace metal gears in certain applications where their advantages align with the specific requirements and operating conditions. It’s crucial to carefully evaluate the application needs, load capacity, temperature range, and other factors to determine if plastic gears are suitable replacements for metal gears.

editor by Dream 2024-04-26

China best OEM Plastic Injection Molding PP/PVC/ABS Cover Plastic Gear for Motorcycle/Auto Parts cycle gear

Product Description

OEM Plastic Injection Molding Cover Motorcycle/Auto Parts

Product Description

Processing program

Our processing has a variety of processing, such as lathes, milling, grinding, boring, drilling, cutting,

etc., to provide you with a multi-faceted service.

|

Product range |

Producr design,mold design, mold making and produce CHINAMFG |

|

Processing Craft |

Mold fabrication, Injection etc; |

|

Material |

ABS,BMC, SMC, AS,PVC,Nylon(PA),PP,PC,PE,POM,PS,HDPE,TPE,TPU etc |

|

Surface finish |

Polishing finish,Texture Finish,Glossy Finish,Electroplating,Painting,Slik print,Rubber Painting etc |

|

Color |

RAL/PANTONE color |

|

Mold Standard |

DME,LKM,FUTA,HASCO etc. |

|

Mould Base |

as per customer’s requirement |

|

Tolerance |

0.01~0.1mm |

|

File Format |

Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

|

Quality Control |

Quality Control |

|

Inspection |

IQC, IPQC,FQC,QA |

|

Application |

All kinds of plastic injection parts being used in a variety of industrial application |

Our processing has a variety of processing, such as lathes, milling, grinding, boring, drilling, cutting,

etc., to provide you with a multi-faceted service.

Rapid tooling

Fast and cost-effective process to create aluminum or steel injection molds for quick turn injection molding. Ideal for rapid prototyping needs or validating product concept for production.

Overmolding

Overmolding is a unique injection molding process that combines 2 or more components together. It is the best practice for the plastic manufacturing of multi-color and multi-layers products.

Insert molding

Insert molding is a custom injection molding process that encapsulates components in a plastic part. It is most commonly used for prototype injection molding designs with threads and holes.

Liquid Silicone Rubber injection molding

Liquid silicone rubber (LSR) is a flexible prototype injection molding process that produces elastic, durable parts. Get custom prototypes and production parts from 15 days.

| Item | Description |

| 1.Mould material | P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 |

| 2.Hardness of steel | vacuum quenching ,nitride,HRC41-47, HRC46-50,HRC60 |

| 3.Inserts / Slider steel | H13 (DIN.1.2344),tempered with HRC46-50 |

| 4.Mould spare parts | H13 (Din 1.2344),tempered with HRC40-45,nitrited with HRC60-62 |

| 5.Mould base | LKM,HASCO |

| 6.Mould cavity | Single / Multi |

| 7.Runner system | Hot / Cold |

| 8.CAD centre for data formats | IGES,X_T,STP & DWG,etc |

| 9.Plastic material | ABS,PC,PE,PP,PS. |

| 10.Mould life | 8 |

| 11.Delivery time | 4-8 weeks |

| 12.Terms of payment | T/T, Paypal, Western Union and so on |

Our Services

1.Product Design,Structural Optimization,Process Optimization.

2.Mold Making,Plastic Molding Parts,Casting Parts,Machining Part.

3.Manage Project,Control The Delivery and Quality of Products.

4.Arranging the Transportation,Customs Clearance and other Matters for You.

In order to ensure the quality of the orders,our independent QC members to carry out strict inspection at each

stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2015 guidelines.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today.

We will sincerely create and share success with all clients.

Advantages:

1. Competitive price.

2. Strict quality control system.

3. Quick mold making and delivery.

4. Advanced equipment, excellent R&D teams.

5. Professional technicians and rich experienced workers.

Quality First,Price Best,Service Foremost!

We assure you of our best services at all times!

If you are interested in any of our products, please send message to us through

below approach!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | ABS |

|---|---|

| Application: | Medical, Household, Electronics, Automotive, Agricultural |

| Certification: | TS16949, RoHS, ISO |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

Can plastic gears be used in automotive applications?

Yes, plastic gears can be used in automotive applications. Here’s a detailed explanation:

Plastic gears have several advantages that make them suitable for certain automotive applications. They are lightweight, have good wear resistance, offer design flexibility, and can operate with low noise levels. However, it’s important to consider the specific requirements and limitations of automotive applications before using plastic gears.

1. Non-load Bearing Applications: Plastic gears are commonly used in non-load bearing applications within automotive systems. These include applications such as instrument clusters, HVAC systems, seat adjustments, and interior components. In these cases, the gears are subjected to relatively low loads and can effectively perform their functions while offering benefits such as weight reduction and cost efficiency.

2. Auxiliary Systems: Plastic gears can also be used in auxiliary systems of vehicles, such as windshield wipers, window regulators, and sunroof mechanisms. These systems typically operate at lower loads and speeds compared to primary powertrain components. Plastic gears can provide reliable performance in these applications while contributing to weight reduction and improved fuel efficiency.

3. Noise and Vibration: Plastic gears have inherent damping properties that can help reduce noise and vibration in automotive applications. This is particularly advantageous in areas where noise reduction is a priority, such as electric window mechanisms or HVAC systems. Plastic gears can contribute to a quieter and more comfortable driving experience.

4. Design Flexibility: Plastic gears offer design flexibility, allowing for complex shapes and customization to meet specific automotive requirements. They can be molded with precision to achieve intricate gear profiles and optimize gear performance. The flexibility in design can lead to improved efficiency, reduced weight, and space-saving advantages in automotive systems.

5. Material Selection: The selection of the appropriate plastic material is crucial for automotive applications. Certain plastic materials, such as engineering thermoplastics like POM (polyoxymethylene) or PA (polyamide), offer higher strength, rigidity, and wear resistance compared to standard plastics. These materials can withstand the demands of automotive environments, including temperature variations and exposure to chemicals or oils.

6. Load-Bearing Applications: While plastic gears are commonly used in non-load bearing or low-load applications within the automotive industry, they may have limitations in high-load or high-torque applications. Metal gears, such as steel or cast iron, are generally preferred for primary powertrain components such as transmissions and differential systems, where higher strength and durability are required to handle the significant loads and forces involved.

7. Environmental Considerations: Automotive applications can expose gears to various environmental factors such as temperature extremes, humidity, UV radiation, and exposure to chemicals or oils. The selected plastic material should have good resistance to these environmental conditions to ensure long-term durability and performance.

In summary, plastic gears can be successfully used in certain automotive applications, particularly in non-load bearing or low-load scenarios, as well as in auxiliary systems. They offer advantages such as weight reduction, design flexibility, and noise reduction. However, when considering the use of plastic gears in automotive applications, it’s important to carefully evaluate the specific requirements, loads, environmental conditions, and material selection to ensure optimal performance and durability.

What are plastic gears and how are they used?

Plastic gears are gear components made from various types of polymers or plastic materials. They offer unique properties and advantages compared to traditional metal gears. Here’s a detailed explanation of plastic gears and their applications:

- Types of Plastic Materials: Plastic gears can be manufactured from different types of polymers, including thermoplastics such as acetal (polyoxymethylene – POM), nylon (polyamide – PA), polycarbonate (PC), and polyethylene (PE), as well as thermosetting plastics like phenolic resins. Each material has its own specific characteristics, such as strength, wear resistance, and temperature resistance, which make them suitable for different applications.

- Advantages of Plastic Gears: Plastic gears offer several advantages over metal gears, including:

- Lightweight: Plastic gears are lighter in weight compared to metal gears, which can be beneficial in applications where weight reduction is important.

- Low Noise and Vibration: Plastic gears can provide quieter operation due to their inherent damping properties that reduce noise and vibration levels.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals, making them suitable for applications in corrosive environments.

- Self-Lubrication: Some plastic materials have self-lubricating properties, reducing the need for external lubrication and simplifying maintenance.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production, due to the lower material and manufacturing costs.

- Applications of Plastic Gears: Plastic gears find applications in various industries and systems, including:

- Automotive: Plastic gears are used in automotive systems such as windshield wipers, HVAC systems, seat adjusters, and electric power steering systems.

- Consumer Electronics: Plastic gears are commonly found in consumer electronics like printers, scanners, cameras, and home appliances.

- Medical Devices: Plastic gears are used in medical equipment and devices where weight reduction, low noise, and corrosion resistance are desired.

- Toy Manufacturing: Plastic gears are extensively used in the production of toys, including mechanical toys, hobby models, and educational kits.

- Office Equipment: Plastic gears are employed in office equipment like printers, copiers, and scanners, where quiet operation and cost-effectiveness are important.

- Industrial Machinery: Plastic gears can be utilized in various industrial machinery applications, such as conveyor systems, packaging equipment, and textile machinery.

It’s important to note that while plastic gears offer unique advantages, they also have limitations. They may not be suitable for applications requiring extremely high torque, high temperatures, or where precise positioning is critical. The selection of plastic gears should consider the specific requirements of the application and the mechanical properties of the chosen plastic material.

editor by Dream 2024-04-23

China OEM CNC Plastic Mould Spare Parts UHMWPE Gear with high quality

Product Description

Product Applications

Widely used in food processing, medical apparatus, chemical equipment, and other industries.

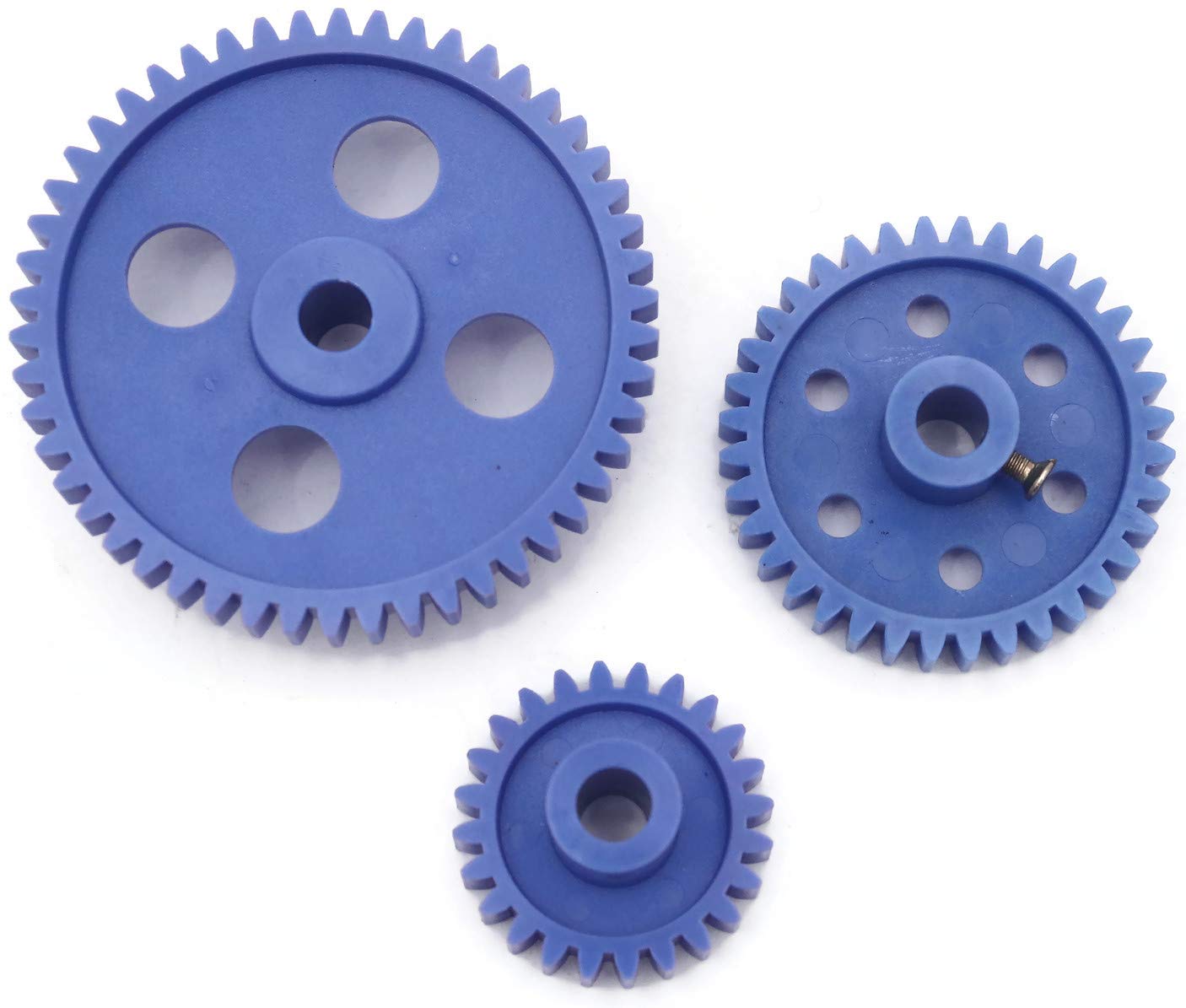

Detailed Photos

Our Advantages

UHMWPE properties ensure that this plastic material is very light, extremely tough, chemically resistant, and has excellent wear resistance.

Key Features:

▪ Excellent sliding properties

▪ High wear resistance

▪ High impact strength

▪ Very good chemical and corrosion resistance

▪ Good noise absorption

▪ Anti-adhesive

▪ High energy absorption capacity and high-stress rates

Product Parameters

| Product | UHMWPE Gear |

| Material | PE |

| Size | Standard/as your requirement |

| Machining Process | Hobbing / Milling / Drilling / Shaving / Grinding |

| Color | White/Black/Green/Nature/Blue/Yellow etc |

| Use | food processing / medical apparatus / chemical equipment / machinery for cHangZhou packaging / machineey machine parts / converying equipment / robotic industry / aerospace industry / semiconductor industry / water treattment industry / ship manufacturing |

| Any small size needs us to cut, we can satisfy your special need | |

Packaging & Shipping

Company Profile

FAQ

Q: Will the inspection be checked before shipment?

A: Yes, every step before loading will be carefully checked to ensure that the products you receive are in good condition.

Q: How long is your delivery time?

A: Generally it is 5-20 days if the goods are in stock. or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples?

A: You can get a sample within 10 days through express.

Q: Will the inspection be checked before shipment?

A: Yes, every step before loading will be carefully checked to ensure that the products you receive are in good condition.

Q: What color can you produce?

A: The usual color is black. The color can also be produced as you require.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory |

|---|---|

| Standard: | GB, EN, China GB Code, JIS Code, TEMA, ASME |

| Surface Treatment: | Polishing |

| Production Type: | Mass Production |

| Machining Method: | CNC Machining |

| Material: | Plastic |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

How do you prevent premature wear and degradation in plastic gears?

Preventing premature wear and degradation in plastic gears requires implementing various measures and considerations. Here’s a detailed explanation of how to achieve this:

1. Material Selection: Choose a plastic material with suitable properties for the specific application. Consider factors such as strength, stiffness, wear resistance, and compatibility with operating conditions. Opt for materials that have good resistance to wear, fatigue, and environmental factors to minimize premature degradation.

2. Gear Design: Pay attention to the design of the plastic gears to minimize wear and degradation. Optimize the tooth profile, gear geometry, and load distribution to reduce stress concentrations and ensure even load sharing among the teeth. Incorporate features such as fillets, reinforcements, and optimized tooth profiles to enhance the gear’s durability.

3. Lubrication: Proper lubrication is essential to reduce friction, minimize wear, and prevent premature degradation. Choose lubricants that are compatible with the plastic material and the operating conditions. Ensure adequate lubrication by following manufacturer recommendations and implementing proper lubrication techniques such as oil bath, grease, or dry lubrication.

4. Operating Conditions: Consider the operating conditions and make adjustments to prevent premature wear and degradation. Control operating temperatures within the recommended range for the plastic material to avoid thermal degradation. Avoid excessive speeds or loads that can lead to increased friction and wear. Minimize exposure to harsh chemicals, UV radiation, or abrasive particles that can degrade the plastic material.

5. Maintenance: Implement regular maintenance practices to prevent premature wear and degradation. Conduct periodic inspections to identify signs of wear or damage. Replace worn or damaged gears promptly to prevent further degradation. Follow recommended maintenance schedules for lubrication, cleaning, and any other specific requirements for the plastic gears.

6. Proper Installation: Ensure that plastic gears are installed correctly to minimize wear and degradation. Follow manufacturer guidelines and recommendations for installation procedures, such as proper alignment, torque values, and fastening techniques. Improper installation can lead to misalignment, increased stress concentrations, and accelerated wear.

7. Optimized Load Distribution: Design the gear system to ensure even load distribution across the gear teeth. Consider factors such as tooth profile, tooth width, and the number of teeth to optimize load sharing. Uneven load distribution can lead to localized wear and premature degradation of specific gear teeth.

8. Environmental Protection: Protect plastic gears from harsh environmental conditions that can accelerate wear and degradation. Implement measures such as sealing mechanisms, coatings, or encapsulation to shield the gears from exposure to chemicals, moisture, UV radiation, or abrasive particles.

9. Quality Manufacturing: Ensure high-quality manufacturing processes to minimize defects and inconsistencies that can compromise the durability of plastic gears. Use reputable suppliers and manufacturers that adhere to strict quality control measures. Conduct thorough inspections and testing to verify the quality of the gears before installation.

By considering these preventive measures, such as material selection, gear design, lubrication, operating conditions, maintenance, proper installation, load distribution optimization, environmental protection, and quality manufacturing, it’s possible to minimize premature wear and degradation in plastic gears, ensuring their longevity and performance.

What are plastic gears and how are they used?

Plastic gears are gear components made from various types of polymers or plastic materials. They offer unique properties and advantages compared to traditional metal gears. Here’s a detailed explanation of plastic gears and their applications:

- Types of Plastic Materials: Plastic gears can be manufactured from different types of polymers, including thermoplastics such as acetal (polyoxymethylene – POM), nylon (polyamide – PA), polycarbonate (PC), and polyethylene (PE), as well as thermosetting plastics like phenolic resins. Each material has its own specific characteristics, such as strength, wear resistance, and temperature resistance, which make them suitable for different applications.

- Advantages of Plastic Gears: Plastic gears offer several advantages over metal gears, including:

- Lightweight: Plastic gears are lighter in weight compared to metal gears, which can be beneficial in applications where weight reduction is important.

- Low Noise and Vibration: Plastic gears can provide quieter operation due to their inherent damping properties that reduce noise and vibration levels.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals, making them suitable for applications in corrosive environments.

- Self-Lubrication: Some plastic materials have self-lubricating properties, reducing the need for external lubrication and simplifying maintenance.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production, due to the lower material and manufacturing costs.

- Applications of Plastic Gears: Plastic gears find applications in various industries and systems, including:

- Automotive: Plastic gears are used in automotive systems such as windshield wipers, HVAC systems, seat adjusters, and electric power steering systems.

- Consumer Electronics: Plastic gears are commonly found in consumer electronics like printers, scanners, cameras, and home appliances.

- Medical Devices: Plastic gears are used in medical equipment and devices where weight reduction, low noise, and corrosion resistance are desired.

- Toy Manufacturing: Plastic gears are extensively used in the production of toys, including mechanical toys, hobby models, and educational kits.

- Office Equipment: Plastic gears are employed in office equipment like printers, copiers, and scanners, where quiet operation and cost-effectiveness are important.

- Industrial Machinery: Plastic gears can be utilized in various industrial machinery applications, such as conveyor systems, packaging equipment, and textile machinery.

It’s important to note that while plastic gears offer unique advantages, they also have limitations. They may not be suitable for applications requiring extremely high torque, high temperatures, or where precise positioning is critical. The selection of plastic gears should consider the specific requirements of the application and the mechanical properties of the chosen plastic material.

editor by Dream 2024-04-19

China Best Sales Injection Molding Unique Part Polyamide Plastic Chain Sprockets Gear supplier

Product Description

Unique Product Polyamide Plastic Chain Sprockets Gear

Description

- OEM size suit for customers’ requirment

- Multiple color can be choosed

- Engraved or embossed logo accepted

- Large order quantity are able to be fulfilled

- Strict quality control system

- In time delivery and thoughtful custom-service

- Certification: SGS, GB/T 19001-2016, ISO9001:2005

| Material | Nylon ,mcnylon,POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion. |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Our Factory

Our Machine

Our Certification

Zhongde is a SGS verified manufacture. We have passed ISO9001:2005 quality control certifacation as well as environment management certification.

For fast quotation, please inform below detials;

1. Product type

2. Size (provide samples or 2d/3d drawings for reference)

3. Material specification (or let us using environment)

4. Quantity request

5. Prefer color

Our Advantage:

OEM service—We are a company specialsing in making OEM mechanical parts in rubber & plastic & pu material, and we produce according to your samples or drawings ,if they are not available, we design according to your requirements and the application. Various existing molds—We have our own mould factory,and after more than 30 years of continued accumulation, there is a very large amount of moulds ,so that we may save the mould cost for you.

Our Packing

Our usual packaging ways are as followings,or it can be as customer’s request.

Shipping:

We will choose the shipping methods according to your request.

Contact Us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities: